Watchmaking is a fascinating blend of art and science, requiring both technical precision and artistic creativity. This complex craft has a rich history, having evolved from the rudimentary timekeeping devices of antiquity to today’s intricate mechanical timepieces and cutting-edge smartwatches.

At its core, watchmaking involves the design and assembly of watches, often by hand. Watchmakers must understand the intricate workings of a watch’s movement (the mechanism that measures and displays time), the casing that houses it, the dial and hands that display the time, and the strap or bracelet that allows the watch to be worn.

In a world where time can be checked on every smartphone, luxury watches stand as a testament to the enduring value of craftsmanship and the art of watchmaking.

Materials. A wide range of materials are used in watchmaking.

1. Metals. Common metals used in watchmaking include stainless steel, gold, and platinum for the watch case and bracelet. Titanium is also used for its strength and light weight. Brass and copper can be used inside the watch due to their anti-magnetic properties.

2. Crystals. Sapphire crystal is often used for the watch face because of its high resistance to scratching. Acrylic or mineral glass are also used in lower-cost watches.

3. Gems. Diamonds and other precious gems can be used for decoration, particularly in luxury watches.

4. Rubber and Leather. These are commonly used for watch straps. Leather offers a classic look, while rubber provides a sporty, durable option.

The Watchmaking Process. Watchmaking requires precise craftsmanship and attention to detail.

1. Design. The process begins with design, where the aesthetic and technical aspects of the watch are decided.

2. Creation of Parts. Each individual component of the watch is created. This can involve machining, stamping, or even hand-carving for high-end watches.

3. Assembly. The watch’s movement is assembled first. This involves putting together many tiny, delicate parts in a precise order. Then, the dial and hands are added, the movement is placed in the case, and finally, the strap or bracelet is attached.

4. Testing. Watches undergo thorough testing for accuracy, water resistance, and other quality measures.

5. Finishing. This can involve polishing the case and bracelet, setting any gemstones, and any other final touches to enhance the watch’s appearance.

Luxury Watchmaking. In luxury watchmaking, the process is often more intensive. High-end watchmakers pride themselves on their craftsmanship, with many components made and finished by hand. Luxury watches often feature complex additional functions, known as complications, such as chronographs (stopwatches), calendars, and moon phase displays. These require additional components and even more precision and skill in assembly.

Luxury watches also often use premium materials, such as 18k gold, platinum, and high-quality leather. Some luxury watches even feature high-quality mechanical movements, which are powered by a mainspring and gear train, rather than a battery. These mechanical movements are appreciated for their intricate craftsmanship and are a testament to the skill of the watchmaker.

The pursuit of luxury in watchmaking is not merely about expensive materials and complex functions. It’s also about the time, effort, and skill that goes into each timepiece. In a world where time can be checked on every smartphone, luxury watches stand as a testament to the enduring value of craftsmanship and the art of watchmaking.

The world of watchmaking is as vast as it is fascinating, with a blend of history, science, artistry, and luxury. Whether you’re interested in the intricate workings of mechanical movements, the artistry of design, or the allure of luxury timepieces, there’s something in this field to captivate your interest.

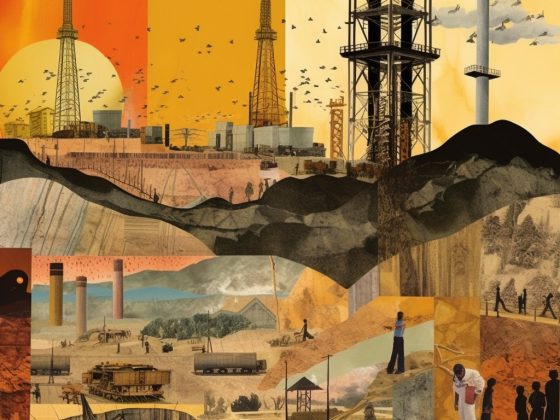

At guzz, our mission is the celebration of human creativity, ingenuity, and expression in arts, crafts, and products. Our inspiration is the human spirit.

For partnerships, product placements, sponsorships, investments, and collaborations, you may reach us at [email protected] for further communications.